Like death and taxes in life, if there’s one thing that’s inevitable in the world of fresh produce, it’s defects! You can’t always avoid them. But as a supply chain stakeholder, whether you are an exporter, importer or a retailer, you can better manage the actions you take when you see fruit and vegetable defects by adding more insight into the kinds of defects that develop, and utilizing a consistent view of what makes your customers satisfied.

Understanding the Types of Defects that Can Develop

Of course, all fresh produce categories will have different defects that are specific to them, depending on the type of produce, where and when they are grown, how they are harvested and more. But in general, there are two main families of defects to consider. We will call them progressive and permanent defects.

1. Progressive fruit and vegetable defects

The key differentiator of a progressive defect is that it will degrade the quality of the fruit over time, often very quickly. Think about defects such as mold, or an open wound. If a fruit or vegetable has an open wound, it will be inedible within a couple of days. If fruit with mold is left with the rest of a shipment, it can quickly spread, extending to the rest of the produce and causing a whole container to be lost. Even when selecting a single piece of fruit for purchase, this is still not fit for sale – it’s produce that a consumer would never intentionally purchase. When it comes to a whole shipment, this can be catastrophic.

2. Permanent fruit and vegetable defects

A permanent defect is non-progressive, a defect that won’t change over time. Consider defects such as scars or closed wounds – these would fall into this category. This defect doesn’t evolve over time, and it won’t impact the entire shipment, but a large percentage of permanent defects could impact the price you get for the produce, or the likelihood of renegotiations or waste. This is because ultimately, a consumer wants fruits without defects at all. However, unlike a progressive defect, most shoppers will buy fruit and vegetables with permanent defects such as some discoloration or bruising if they cannot find any without.

As a trader or an importer, you know that shipments with a high percentage of progressive defects may well be impossible to sell to your customers, but permanent defects trigger a more complex decision-making process. After all, depending on the quality threshold dictated by each customer and other factors such as how much of that fruit is currently available in the market, you may be able to sell the shipment as usual, or at least a percentage.

The question is, how can your inspectors ascertain this ahead of time?

The Inspection Process for Fresh Fruit and Vegetable Defects

Most inspections are a matter of sampling a percentage of a particular shipment, and manually spotting defects from the samples to gather information. The inspectors then use this data to work out statistical significance across the whole shipment. If you test 100 samples of table grapes and find that two of these have scarring, you can say that 2% of the shipment has scarring.

At this point, the traditional method of shipping this produce to the customer involves a lot of guesswork. The exporter generally doesn’t know which customer the shipment is going to. Even when they do, they don’t know what the buyer is expecting, or what their standards for quality are. Each inspection is an isolated event, with no prior information provided. They have a gamble on their hands. Either they send the shipment to the high-quality buyer where they will get more return for their produce, but may be risking rejection, or they send it to the open market where they will get a very low price for their shipment, which may not be worth their efforts.

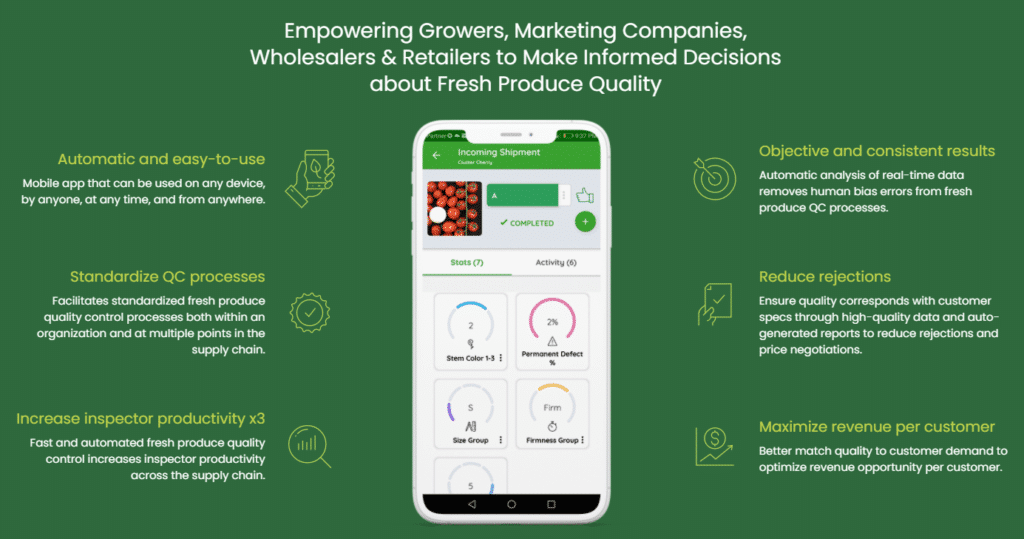

The Clarifruit Difference: One Centralized System for Historical and Real-time Data

With a single, centralized quality control system for all customers, this all changes. The exporter has real-time access to previous data and accurate information about the quality expectations from each buyer. They can go back into the system and see what happened the last time they sent table grapes with a similar defect or percentage of defects attached, or capitalize on our “comparison analytics” to grade the inspected crop based on specific customer specifications. They can make better and smarter decisions based on actual information rather than guesswork. In short, the exporter can find the optimal customer in terms of price and quality for each specific shipment.

From the customer side, there is also a lot more control over how they manage their imports. The customer can categorize defects any way that they choose, such as by progressive or permanent defects, or even within these categories, by low, medium or critical defect status. For example, in a particular season, a customer may be happy to accept a shipment with permanent defects such as scarring, but only up to a low amount. At a later date, when this produce is harder to come by, they can adapt their requirements to accept fruit with a medium status.

The Clarifruit platform allows for full transparency into customer requirements. This can also be managed according to a specific produce type. What is acceptable in lemons might not be in tomatoes, cherries or grapes. This level of control brings intelligence and insight to the process for the first time.