Fresh produce shrink could be the invisible mouth at your supermarket or grocery store’s table, reducing profits and exacerbating food wastes. According to some estimates, much of this waste lies at the retail end with approximately 12% of fresh fruit and 11.5% of vegetables lost at store level.

Here, we explore the options retailers have at their disposal to reduce produce shrink. In particular, we’re taking a look at the roles of quality assurance and quality control, and how they should come together in a modernized fresh produce retail business.

Fresh Produce Quality Assurance (QA)

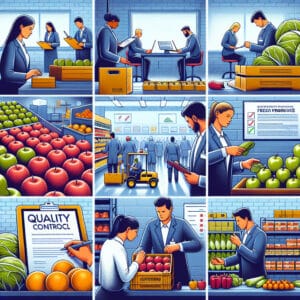

Quality Assurance is a process-oriented approach that focuses on preventing defects and ensuring quality in the production process. It is about designing, implementing, and maintaining a systematic and proactive process to prevent problems from occurring in the first place.

QA encompasses the entire supply chain and looks at the bigger picture. It involves developing and enforcing standards and methods to ensure that every step of the process, including post harvest practices, cold chain management, storage conditions, and inventory management. QA professionals are interested in whether these processes adhere to quality standards that prevent quality issues.

Typical quality assurance activities include:

- Establishing quality standards and protocols for the supply chain.

- Training and development programs for employees.

- Implementing and monitoring quality management systems.

- Developing a systemic approach to handling real-time data for continuous improvement.

Overall, the goal of QA is to enhance and ensure the production process’s quality, thereby indirectly affecting the final product’s quality. It aims at building confidence among stakeholders that quality requirements will be fulfilled.

Fresh Produce Quality Control (QC)

In contrast, Quality Control is product-oriented. In the QC process, inspectors examine and test the fresh produce against specific quality criteria. QC is reactive, identifying and correcting defects in the final products.

QC managers have a variety of responsibilities like:

- Inspection and testing of incoming and stored products.

- Assessing fresh produce quality at the store level.

- Identifying defects or deviations from quality standards.

- Taking corrective actions to address identified quality issues.

The Evolving Role of Retailers in Quality Control: an Opportunity to do More

Retailers have always played a pivotal role in fresh produce quality control, usually at 2 stages: at the intake, and when stacking shelves. But the retail environment has become more complex, with online orders and deliveries making up a larger share of grocery stores’ operations. This puts them on the frontline of quality control across many more touchpoints.

This provides new opportunities for retailers to curtail waste and reduce shrink – but only if they have ways to handle the additional complexity and technical demands that this brings. Traditional, manual quality control methods are not able to provide the standardization and agility that this demands.

Integrating QA and QC with Clarifruit

While QA and QC serve distinct functions, they are complementary. Quality Assurance creates an environment conducive to producing high-quality products, while Quality Control ensures the products are in fact up to standard. When it comes to fresh produce shrink, QA and QC should work in tandem to establish systems that mitigate the risks of defects, and then accurately identify those that do occur.

Clarifruit essentially bridges the gap between QA and QC by providing a tool that can be used for both preventive and corrective measures. It offers a technological solution that supports the QA process by ensuring quality standards are met throughout the supply chain, for all stakeholders. It also enhances the QC process by providing a means for thorough and accurate inspection of produce. Contact us to learn more about how Clarifruit could help your business reduce shrink, improve quality, and increase customer satisfaction.