AI-Driven, Automatic Quality Control Solution

The value of any data analytics output depends on the quality of the raw data input. That’s why we designed an end-to-end quality control software solution that can collect objective and consistent data at the inspection point, and only then analyze it and derive operational insights that will be instrumental in reducing waste and maximizing profitability throughout the supply chain.

Meet the Clarifruit Quality Control Platform

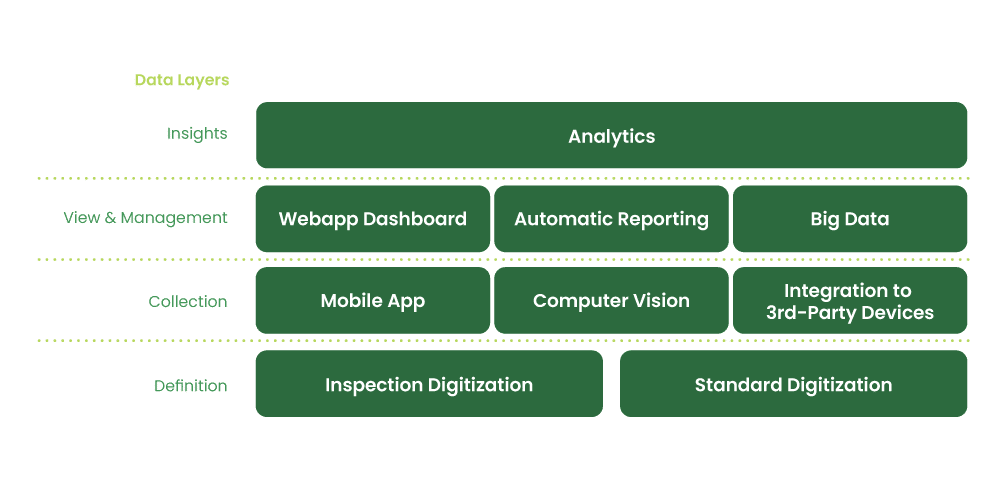

The Nine Building Blocks of the Clarifruit Platform

The Clarifruit solution is composed of nine technological building blocks. Across these nine elements, four layers of data work to bring incisive knowledge to growers, marketing companies, wholesalers, and retailers in the fresh fruit and vegetable supply chain.

Insights

With each inspection, the Big Data library grows, and analytics are run on uploaded data to derive unique insights that are utilized to boost operational efficiency and maximize profitability.

View & Management

Clarifruit’s cloud-based Management dashboard hosts and manages all uploaded data from every inspection completed using the mobile app, allowing for real-time viewing of the data.

Every completed inspection results in an automatically-generated report, self-customized by the customer.

A Big Data infrastructure stores all raw data related to the fresh produce attributes, time, location, user info, inspection process duration, quality standards, and other relevant information.

Collection

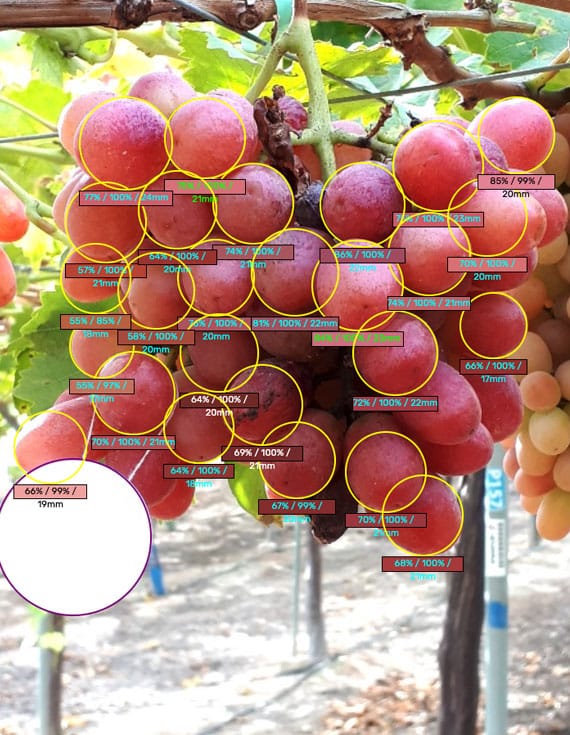

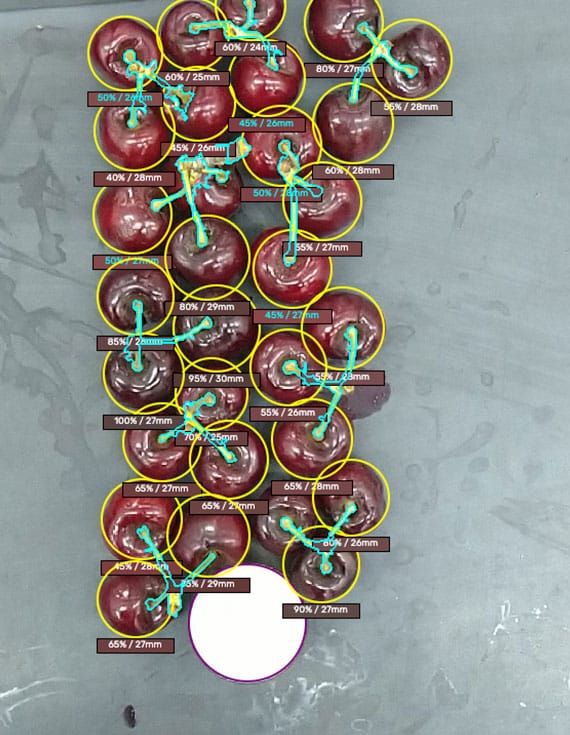

The Clarifruit mobile app serves as the central infrastructure for collecting all QC data. Our computer-vision and machine learning technologies instantly analyze external fresh produce attributes such as size, color, stem color, and defects.

Clarifruit’s platform also integrates wirelessly with third-party industry devices to evaluate internal fresh produce attributes.

Definition

Define and digitize the inspection process (e.g. pre-harvest, intake) and required quality standards that determine the overall grade of an inspected produce category

With each inspection, the Big Data library grows, and analytics are run on uploaded data to derive unique insights that are utilized to boost operational efficiency and maximize profitability.

1 of 4Clarifruit’s cloud-based Management dashboard hosts and manages all uploaded data from every inspection completed using the mobile app, allowing for real-time viewing of the data.

Every completed inspection results in an automatically-generated report, self-customized by the customer.

A Big Data infrastructure stores all raw data related to the fresh produce attributes, time, location, user info, inspection process duration, quality standards, and other relevant information.

2 of 4 The Clarifruit mobile app serves as the central infrastructure for collecting all QC data. Our computer-vision and machine learning technologies instantly analyze external fresh produce attributes such as size, color, stem color, and defects.Clarifruit’s platform also integrates wirelessly with third-party industry devices to evaluate internal fresh produce attributes. 3 of 4

Define and digitize the inspection process (e.g. pre-harvest, intake) and required quality standards that determine the overall grade of an inspected produce category

4 of 4