Stay ahead of the game with Clarifruit's blog. From fresh produce QC updates and new releases to supply chain tips and tricks, our blog is your go-to source for all things produce.

Retailers are Struggling with Mounting Waste. How Can QC Help?

Food is the largest component taking up space in US landfills, with 40 million tons being discarded every single year, 40% of this happening at

How new QC technology is revolutionizing logistics in the produce industry

Clarifruit has proven to be a transformative platform enabling PROTO to inspect tens of thousands of different fruits throughout the year, saving on inspection time, reducing rejection rates, and ensuring quality standards are fully met.

Lessons Amplified from the Global Produce and Floral Show 2022!

We had the most amazing time at last month’s Global Produce and Floral show 2022! Now that the dust has settled we want to share key messages.

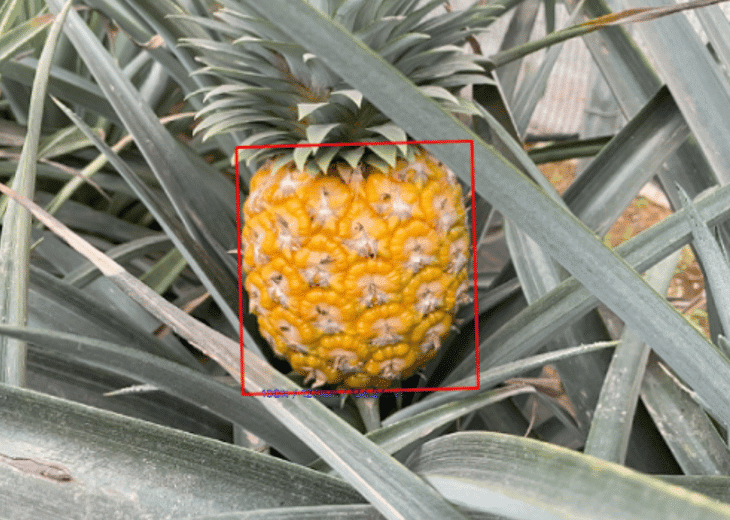

Introducing LiDAR Technology for Unparalleled Accuracy When Sizing Fresh Produce

Clarifruit has proven to be a transformative platform enabling PROTO to inspect tens of thousands of different fruits throughout the year, saving on inspection time, reducing rejection rates, and ensuring quality standards are fully met.

Reducing Global Food Waste with Clarifruit

Food waste is an enormous problem worldwide, with the United Nations reporting that nearly half of all fruits and vegetables are wasted each year, making this category the most wasted food item in the world. What’s causing all of this loss, and how can automated Quality Contol (QC) make the difference?

Creating a Consistent Language for Fresh Produce Quality Control Is a Win for Buyers and Sellers

When it comes to the fresh fruits and vegetables value chain, stakeholders will regularly find themselves standing on opposite sides of the table. After all, buyers gotta buy and sellers gotta sell! These goals should be complementary, and yet there’s a lot of friction between the two parties. What’s causing all the conflict? A seemingly simple language barrier, and it’s all centered around quality control.

Commercial Blueberry Harvesting: How is the Blueberry Industry Improving Quality Control?

It’s the start of blueberry harvest season, and we’re here for it! As blueberry production grows in leaps and bounds, stakeholders across the supply chain are looking to improve the ratio of fresh blueberries to other forms, as fresh berries can fetch double to triple the market value of those which have been processed. In this blog post, we explore how the blueberry industry can improve its quality control processes through automation, big data and Artificial Intelligence.

Separating Quality Grading from the QC Process – a Game Changer for Fresh Produce Supply Chain Management

One of the most pressing issues in the fresh fruit and vegetable supply chain industry is the lack of a common language. Each customer provides a comprehensive list of instructions for anything from color, shape and size to Brix levels and defect tolerances. This PDF can be twenty pages long, and an average marketing company or wholesaler’s customer list could include anywhere from 50-100 customers. One customer’s A-standard is another customer’s C-standard. When we built the Clarifruit platform, we kept all of this in mind and created a smart solution that allows businesses to sidestep the complexity of multiple languages. Here’s how it works.

Fresh Produce Quality Control: Legacy vs AI-Powered Solutions

Agriculture and farming are believed to be the world’s oldest professions, but are your processes for quality control living in the stone age? We take a look at the traditional methods still in place for some of the largest companies in the world, and how innovators are using the latest technologies to digitize and modernize to reduce waste and drive up revenues.

Listen Up Retailers: It’s Time to Reduce Waste with Connected Front-Store Quality Control

Retailers are receiving a lot of merchandise and obviously, the consumer will not buy everything. When we drill down into fresh produce specifically, around 12% of fruit and 11.5% of vegetables arrive at the grocery store and are never sold, which translates into a serious hit for retailers’ bottom line. So how can technology help the savvy retailer get ahead?

Subscribe to our newsletter

Sign up to get the latest news and developments in the fresh produce quality assurance and control industry, and stay in the know about all things Clarifruit.