Reducing Global Food Waste with Clarifruit

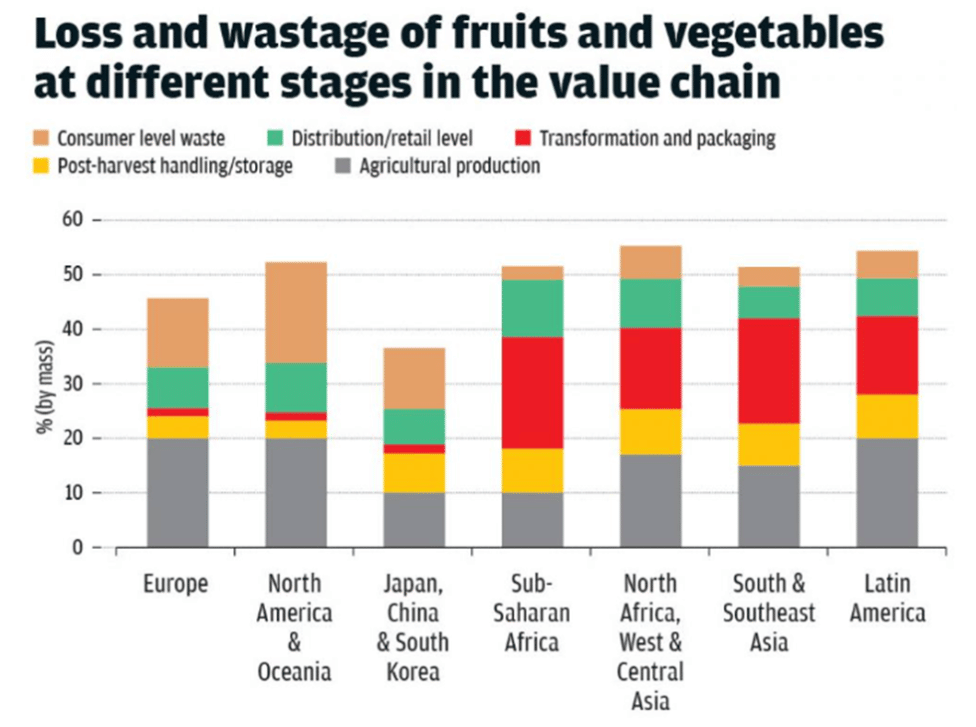

Food waste is an enormous problem worldwide, with the United Nations reporting that nearly half of all fruits and vegetables are wasted each year, making this category the most wasted food item in the world. What’s causing all of this loss, and how can automated Quality Contol (QC) make the difference?

The global food waste problem

While food waste is a universal issue, the stats differ between regions. For example, in the US, consumer-level waste is a much greater issue than anywhere else, while in Africa, the largest losses are at the transformation and packing stage. Either way, that’s billions of people who could be benefiting from the fruits and vegetables and seeing greater food security if we could improve food loss and waste.

Across the board however, there is a huge amount of waste during Agricultural production and post-harvest handling and storage. Based on Harvard University Research, one study estimates the world is currently producing just 1/3 of the fruits and vegetables the population needs, showing how important it is to reduce food wastage.

Food waste is bad for the environment, a poor use of resources, limits the revenues of the stakeholders across the value chain, and worst of all – is much more preventable than people realize.

Why does food waste occur?

To understand this global food problem, let’s think about the world’s most popular produce category – the tomato. While one study uncovered that in one case 86.7% of a tomato crop was thrown away due to weird shapes or sizes, even if we think about much lower numbers, this is still a huge amount of food. The name given to this kind of waste is “quality mismatches.”

The farmer or grower picks a harvest of tomatoes, and then thinks about their buyers. If they can’t find the right buyer for the produce, it gets wasted. The farmers don’t want to take the risk to send the produce “just in case”, because the costs of shipping and packaging are great, and a rejection would represent a heavy loss to their bottom line.

We can split the global waste problem into three key reasons:

1. Lack of standardized language

Meet the Fresh Produce version of “people speak different languages”. Each stakeholder has their own idea of what a high-quality tomato is, and in the fresh produce industry, there are no agreed standards for what a Grade A tomato is, or a Grade C.

Instead, the buyer builds his own 20-page PDF document with his own quality specifications outlined, and this completely unstructured document is left to be interpreted by the seller. That means that while a supplier might consider this crop to be chock-full of Grade A produce, the buyer might have a different description in his own quality specs, and this will be true for each and every buyer. The shipment arrives at the buyer’s dock, and the buyer rejects it immediately, as although they both consider the shipment to be Grade A, it doesn’t meet their specific expectations.

For the seller, this issue is a big one, as a rejection can cause a serious hit to their revenues. Why take the risk of sending a shipment which is borderline to the buyer, if they can simply send it to a less demanding buyer and be guaranteed a sale? For the buyer, this causes a stock issue. They want to be certain that they will fill their shelves, and yet they can’t be certain that the fruits and vegetables are the right quality until they arrive.

2. Subjectivity

Fresh fruits and vegetable quality control is also about a lot more than just a simple grade. Under the grade, there are dozens of parameters, from size and color, to numerous defects which vary between different fruits and vegetables. To one stakeholder, a tomato will be large, or have minor defects, while to another, it will be medium-sized, and the defects will be more severe. The same is true when it comes to an objective view of the produce’s color or shape.

While the language is the major problem, there is also definitely an issue of objectivity, or lack of it, going on. The fact that the current quality inspection process is primarily manual is a key reason for that. If you can’t trust that the buyer will have the same view as you about whether a tomato is red or orange, how can you know that they will accept your price or your shipment at all?

3. Lack of real-time data

Of course, there are also going to be issues when it comes to the process of how the fruits and vegetables are picked, handled, stored and transported. As you can see in the graph above, a large percentage of the waste happens at these stages of the journey.

Stakeholders need real-time visibility into where problems are occurring, for example recognizing that cold storage has damaged a selection of pallets, or that the quality reduces after using a certain transportation company or warehouse, in order to optimize matching of produce quality

Understanding the value of Clarifruit

When we think about these three problems, they can all be solved (or meaningfully mitigated, as a first step) with next-gen technologies that have significantly developed over the last decade in other industries, namely the software industry. Digitalization, AI and cloud-based technologies can standardize languages, add objectivity and enable real-time visibility of data, which is exactly what Clarifruit offers with its automated solution for quality control.

Inspectors simply take a photo of the produce, and Clarifruit’s computer vision technology will provide an objective grading (of external attributes) that doesn’t change from inspector to inspector. This removes the issue of objectivity from the equation. By creating digital specifications inside Clarifruit, you can translate your buyer or seller language into any other stakeholder’s, so that you can view how your grading system compares to theirs.

For example, as a seller, you run an inspection on a tomato yield, and it comes up Grade B. You can then automatically view your results side by side with the buyer specs, and see that this is actually one of your buyer’s Grade A, therefore getting a better price for the crop, while feeling confident that you won’t experience any rejects or renegotiations. As you can do this at scale, you can quickly see what a specific shipment would mean to each of your potential buyers, and then make the right choice.

As inspections can be run as many times as you need, you can task staff with taking inspections at critical points along the journey, from pre-harvest, to storage, transportation and more, allowing you to get more granular insight into your produce and understand when and how issues occur. This means you can make intelligent changes to your process to get better outcomes moving forward.

Altogether, using Clarifruit can reduce the waste at the supplier segment by 20%, which is a 2% reduction in waste overall. This translates to millions of fruits and vegetables every single year, saving the economy $18 billion, and supporting the UN’s Sustainable Development Goals of Zero Hunger and Responsible Consumption and Production.

We invite you to take a proactive step in addressing the pressing global waste crisis by applying here to experience Clarifruit firsthand. By joining our platform, you become an integral part of the solution, contributing to the reduction of unnecessary waste in the fresh produce industry. With Clarifruit, you’ll not only gain access to cutting-edge technology but also play a vital role in promoting sustainability and efficiency within the sector. Your participation empowers you to make more informed decisions, minimize over-purchasing, and reduce the environmental footprint associated with excess waste. Together, we can work towards a more sustainable and responsible future for the entire fresh produce supply chain. Don’t miss this opportunity to be a catalyst for positive change—apply now and be part of the solution that our planet urgently needs.