On the simplest level, Artificial Intelligence (AI) is any process where a decision is taken by a machine instead of a human. An AI model is an example of AI where data is used to train a model with real-world examples until the machine is good enough to perform a particular task. At first glance, it might not seem like AI and fresh produce quality control have much to do with one another. But here at Clarifruit we’ve found a synergy that opens up new opportunities for stakeholders across the value chain, from growers and packing houses, through to retailers’ distribution centers and end-users.

How does AI Out-Perform Humans Here?

The first thing to understand is how complex a task fresh produce quality control really is. There are many kinds of fruits and vegetables, and each have their own attributes that are measured in subtly different ways. For a computer, it’s complex to look at a picture of a certain produce type and take these measurements or extract quality attributes with a high level of accuracy, and it takes a long time to make it happen using automation. In fact, we needed to use a huge amount of real-world data, and create an in-depth training cycle before we released our computer vision technology.

However, the benefits of using AI rather than human inspectors are so great, that they are worth the effort it takes to develop a complex algorithm and train a model to make these decisions.

How Does Clarifruit Integrate AI into Fresh Produce QC

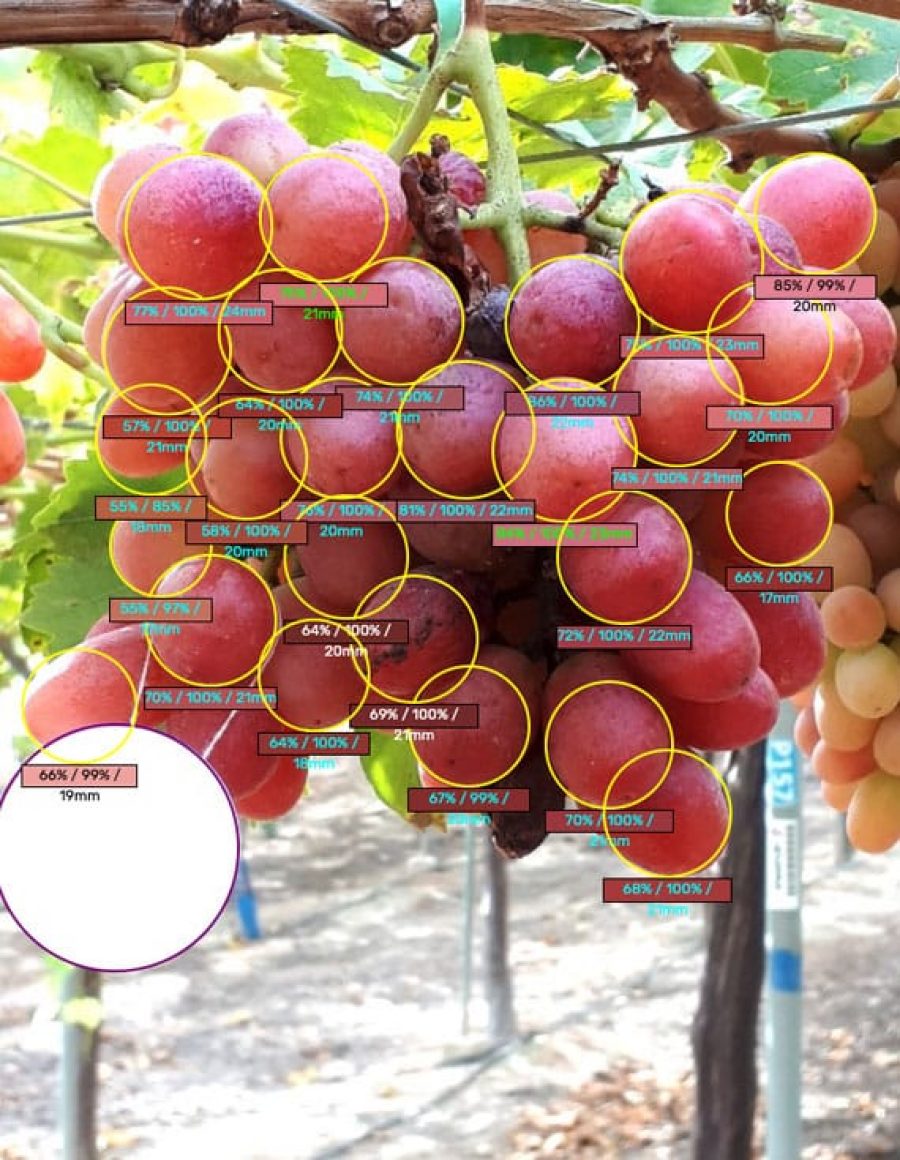

When we built Clarifruit, we preconfigured the settings and the AI-based models so that the platform understands what attributes should be collected. From the size of each piece of fruit, which is traditionally a long, tedious and error-prone process for manual inspectors, to the defects of each product type, or the color of the produce, that could be distorted by lighting or time of day. We also knew that we had to ensure the results could be saved in a smart future-focused way, easily improving on the manual process of writing information on pen and paper, or inputting it to an Excel spreadsheet.

We used more than a million images to train multiple models that enabled a machine to recognize fruit’s attributes, including adjusting for variations in inspection conditions such as different lighting, shading and barriers to view. Through a lengthy period of collecting data, annotating and labeling the information with granular detail, we’ve created technology based on algorithms that are actually more accurate, and vitally – more consistent than the human eye.

Applying a lab-tested model in the real-world

In practice, this means that many of our customers have tested our AI in the real-world, inspecting manually at the same time as with our application, and been able to validate the application’s accuracy ‘in the wild’. With our proprietary algorithms we’ve achieved something that’s coveted in the AI community, a model that can be transferred from the lab to the real-world and continue to improve on its excellent results.

Using Clarifruit’s advanced computer vision technology running on a mobile device, the whole process is now done automatically – all attributes needed for the specific fruit are saved into the system right after the picture is taken and analyzed by Clarifruit’s AI models and algorithms. Learn how it works here.

What are the Benefits of integrating AI and Fresh Produce Quality Control?

So now we know that the model works, and that the AI can be more accurate than humans, why do you need it? Here are the highlights:

More Speed

Think about how much more can be achieved if your fresh fruits and vegetable quality control is just a matter of taking a photo? Let’s say traditionally you sampled 1% of your produce, you can now test 5% or even 10%, scaling upwards without adding more effort, and making the information far more accurate, too.

Greater Consistency

No more subjective reports or mismatches between stakeholders over the true quality of fruits and vegetables. The AI works the same way every time, everywhere. This means less rejections and price renegotiations, more consistency over your operations, and more insight into your revenues and costs each month, with no surprises.

Complete Objectivity

Your quality control is not dependent on an inspector, or on the condition of your environment including variables such as weather, time of day, or light levels. No matter who completes the quality control assessment, your results are the same, saving duplicate testing by stakeholders on opposite sides of a purchase agreement for example. Using AI means unarguable results.

Ease of Use

Training new inspectors is a much easier and faster task with an AI-driven QC process, and the quality control itself can also be done remotely, streamlining the efficiency from end to end. The inspector has now become merely the collector of the data rather than responsible for making subjective “calls” on the quality of the produce. This means they do not need to be a fresh produce quality expert with significant experience.

Less Waste

Traditional methods of quality control can cause damage to the very fruits and vegetables that are being inspected. Think about fruit like grapes or bananas that need to be taken apart to measure certain attributes. You’re also having less waste due to returns, offering everyone in the value chain clear visibility into the value and quality of a shipment.

How Does it Work?

Let’s look at how we make it work in practice. As we’ve said, AI is a central part of our platform, utilizing computer vision technology. The user simply takes a photo of the produce, and the machine will analyze the images, and extract measurements and attributes such as color, size, stem color, defects, and more.

Taking this further, the AI will also automatically detect the variance between the different fruits in a selection, and even identify color variance in a single fruit for example, such as a tomato that is partly green and partly red. The app can also measure the shape to uncover fruits that are smaller than optimal, or shaped differently, for example bananas with an unusual curve ratio.

Understanding the Continuous Feedback Loop

An additional benefit of an AI-based solution that leverages real-world data is that the more the platform is used, the better the model will get. We also continue to add information to improve the accuracy of the model. Over time, more edge cases are discovered, and the algorithm’s predictions naturally improve.

Here at Clarifruit, we’re very proud of the capabilities of our cutting-edge quality control technology, and we’re continually working on expanding the potential of our AI. Next on the roadmap, and already in development behind the scenes will be a greater understanding of internal attributes, using NIR, Near-infrared Spectroscopy. Watch this space!

Want to see the benefits of AI for your fresh produce use case? Let’s schedule a call.